Açık Rotor

NASA and General Electric have teamed up with French industry to revive a type of fuel-efficient aircraft engine shelved in the 1980s, in an effort to tackle aviation carbon emissions and high fuel costs.

The "open rotor" engines, despite their relatively green characteristics, will still be unpopular with many anti-aviation campaigners as they are significantly noisier than ordinary turbofans.

Sound and fury, signifying green?

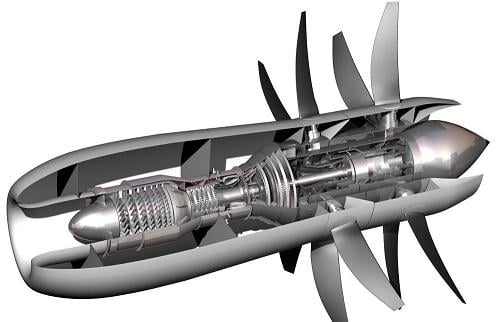

Open rotor engines work in a fashion not dissimilar to today's high-bypass turbofans, which use a central gas-turbine core to drive a larger-diameter fan which rams a lot more air through the outer part of the engine ("bypassing" the central jet, hence the name). This makes for much better fuel efficiency than the turbine and its compressor alone.

But the fan on current engines is still enclosed inside the nacelle, which cuts down on noise but limits the area of air on which the blades can work. For true efficiency, it would be better to use larger fan blades still, ones so long that it would no longer be practical to fully enclose them and hang them beneath an airliner's wing. It's thought that two counter-rotating fans would give best results, saving as much as 25 per cent of the fuel an airliner now uses for a given journey - but at the cost of a lot more noise.

The result is an open rotor engine, something between a turboprop and a turbofan. Back in the 1980s, with the oil crisis of the 70s still fresh in everyone's memory, General Electric planned to put an open rotor engine on the market. The result was the GE36 design. By the time the GE36 was ready to go, however, fuel prices had fallen and there wasn't enough interest in a new efficient engine, so General Electric never actually launched it commercially.

But the soaring oil prices seen before the recent economic slump - now climbing again - combined with governmental plans for massive levies and crackdowns on carbon emissions have made aviation industry chiefs think again. GE and NASA announced jointly that they would restart wind-tunnel test work on open rotors last year, and yesterday they said that the necessary test rigs - last used for the GE36 work in the 1980s - have now been refurbished. Tunnel tests at NASA's Glenn research centre are expected to begin this summer.

"The tests mark a new journey for GE and NASA in the world of open rotor technology," said David Joyce, president of GE Aviation. "These tests will help to tell us how confident we are in meeting the technical challenges of an open-rotor architecture. It's a journey driven by a need to sharply reduce fuel consumption in future aircraft."

France's Snecma - collaborator with GE on the CFM56 joint engine series - will also participate.

GE, NASA and Snecma aren't the only ones looking for new engine technologies to cut fuel consumption on future airliners. Pratt & Whitney are pushing their "geared turbofan" concept, and British-headquartered Rolls-Royce has expressed its corporate view that open-rotor is the way ahead.

The big snag for open rotors is admitted by all concerned to be noise. A big part of the protest attendant on airport expansion efforts like those planned for London's Heathrow is actually driven by local dislike of aircraft noise rather than ecological concern as such. Many people don't really care about carbon emissions so long as planes stay quiet.

The conflict between reducing CO2 and reducing noise is indeed already apparent. According to Professor Ian Poll, Fellow of the Royal Aeronautical Society, noise concerns are already hurting the environment. Today's A380 double-decker superjumbo, he says, already has a "cruise burn fuel penalty" which is the result of design compromises made to make it comply with noise regulations.

Many would argue that everyone should simply fly less, of course, so reducing the amount of fuel burned and emissions given off without the need to have noisier greener planes. But a 25 per cent cut in flights - to deliver the same reductions you could get by going to open-rotor - would seem likely to be painful economically.

And with recent research indicating that railways can actually hurt the environment more per passenger mile than airliners, flying less could even be a retrograde step in ecological terms. ®

GE and NASA plan to test a number of open-rotor fan blade systems for jet aircraft engines Image via GE Aviation

GE Aviation and NASA will run a wind tunnel test program over the northern summer to evaluate and test counter-rotating fan-blade systems for open-rotor jet engine designs. The newly improved rig for testing was originally used by GE and NASA in the 1980s on scale models of counter-rotating fan systems, which led to the development of the GE36 engine. The test program also demonstrated that an open-rotor jet engine consumed 30 percent less fuel compared to similar-sized conventional jet engines. Just think what a 30 percent drop in fuel consumption would deliver today, not only to an airline industry struggling to keep ticket prices down, but also the positive benefits to the environment.

GE is confident that the significant improvements to its computational aero-acoustic analysis tools, over the past 25-odd years, will make running the program a little easier this time around. Both GE snd NASA expect to gain a better analysis and understanding of open-rotor systems by testing a number of new and more sophisticated fan systems in the wind tunnel. Rather than running full engine tests, a number of configurations will be tested in simulated flight conditions. Factors such as aeronautical design and acoustic levels will be considered in terms of the actual operating environment.

"The tests mark a new journey for GE and NASA in the world of open rotor technology," says David Joyce, president of GE Aviation. "These tests will help to tell us how confident we are in meeting the technical challenges of an open-rotor architecture. It's a journey driven by a need to sharply reduce fuel consumption in future aircraft."

Testing

The wind tunnel facilities are located at NASA's Glenn Research Center in Cleveland, Ohio, and testing is expected to continue for the rest of this year and into early 2010. The tests will mirror those run in the 1980s, with the first tests using blades that were designed for the original GE36 jet engine.

The plan is to test six different blade designs in the wind tunnel. The designs will feature blades that are scaled to one-fifth the size of regular blades and will consist of two rows of counter-rotating blades. Blade efficiency and performance will be tested with the advanced computerized data acquisition systems during simulations, featuring high-altitude cruise conditions.

Benefits

The main criticism of open-rotor jet engine design is the difficulty in reducing the amount of noise generated by these engines, particularly in commercial air space. Noise shielding or noise cancellation techniques may be required to ensure aircraft meet noise requirements. However, given the benefits of lower fuel cost to the airline industry and the positive impact on the environment, it may not be too long before aircraft of the future feature open-rotor jet engines.

The counter rotating test rig at NASA's Glenn Research Center enables unique testing, such as the current collaborative testing of open rotor technology by Glenn and General Electric Co., or GE. Image Credit: NASA

As aeronautics technology continues to evolve, researchers from government agencies and companies around the globe are trying to answer these questions. Developing and testing technology for planes that produce significantly less noise and have a decreased environmental impact are two of NASA's key research goals.

Several NASA centers, including the Glenn ResearchCenter in Cleveland, are involved in a multitude of initiatives regarding new aeronautics technology. Glenn scientists, engineers and researchers are working on several NASA projects and collaborating with the aerospace industry to investigate and test new technologies.

Through a Space Act Agreement, Glenn is working with General Electric Co., or GE, to test new technology for a jet engine with two high-speed propellers on the outside, called an open rotor. This effort, initiated under the Subsonic Fixed Wing Project, and now supported by the Environmentally Responsible Aviation Project, of NASA's Aeronautics Research Mission Directorate in Washington, includes testing of the open rotor technology in a Glenn wind tunnel with a test rig designed and built specifically for open rotor testing.

The test rig allows the one propeller to spin in one direction while the propeller directly behind it spins in the opposite direction. This counter-rotating rig is a special piece of equipment. Very few exist, and none are available commercially in the United States.

"We bring the drive rig and the test capability and the test facility, the 9'X 15' wind tunnel. GE brings the design capability and fabrication capability for the open rotor systems," says Brian Fite, the chief of the Acoustics Branch at Glenn. "It is a good fit of the capabilities that each institution has to offer."

The unique shape and design of the high-speed propeller allows airplanes to fly at speeds close to that of airplanes with jet engines. Jet airplanes currently fly much faster than airplanes with standard propellers. Counter rotating propellers increase fuel efficiency but increase the amount of noise produced. Careful design of the open rotor blades is required to reduce the noise both outside and inside the passenger cabin.

"Our goal is to validate noise reduction with an open rotor system while still getting a good fuel burn performance metric," Fite says. Quieting the noise to make open rotors acceptable to the flying public is a major technical challenge.

NASA studied an earlier form of open rotor technology, called a prop fan, in the late 1980s and early 1990s. The Glenn team began this current testing by reevaluating the center's data from earlier studies to compare it to the new data derived from the new experiments. Some Glenn personnel from the original tests still work at Glenn, and they have provided invaluable input.

Glenn stored the counter rotating test rig from the original experiments, and so Glenn was able to restore it for new use with this testing.

"It had been so long since this kind of technology had been looked at; everyone else got rid of their experimental test capability for it. Glenn stored our rig at Plum Brook, and we were able to refurbish it," says Dale Van Zante, the Environmentally Responsible Aviation Project's open rotor research team lead. "With the run-up in fuel prices over the last few years and other environmental issues, engine companies and air framers are again looking at the open rotor technology. Potentially, it gives a big decrease in fuel burn -- gas mileage gets a lot better with that kind of system."

On this open rotor, one high-speed propeller spins in one direction while another high-speed propeller directly behind it spins in the other direction. Image Credit: NASA The open rotor collaboration began with the signing of a Space Act Agreement between NASA and GE in 2008. GE designed and manufactured the rotors that would be tested, while Glenn refurbished, tested and fine-tuned the counter rotating rig. GE then brought its hardware to Glenn, and began testing last summer. The acoustic and performance data generated will help engineers determine how the open rotor concept could be refined.

On this open rotor, one high-speed propeller spins in one direction while another high-speed propeller directly behind it spins in the other direction. Image Credit: NASA The open rotor collaboration began with the signing of a Space Act Agreement between NASA and GE in 2008. GE designed and manufactured the rotors that would be tested, while Glenn refurbished, tested and fine-tuned the counter rotating rig. GE then brought its hardware to Glenn, and began testing last summer. The acoustic and performance data generated will help engineers determine how the open rotor concept could be refined. The testing has been taking place in the 9'x 15' Low-Speed Wind Tunnel at Glenn, with the testing conditions set up to simulate takeoff and landing. Low speed testing is scheduled to be completed in spring 2010. Testing to measure cruise performance, a major contributor to potential fuel burn reduction, is scheduled to be completed by the end of 2010.

The GE blade design is mounted on Glenn’s counter rotating test rig. For each test, the blades' operation is assessed for acoustic and aerodynamic performance. Variables are explored, including the angle of each blade and the geometric relationship between the rows of blades.

Testing will continue with diagnostic assessments such as using pressure sensitive paint on the propeller surface to explore how the aerodynamic pressure, or loading, is distributed on the blades. Glenn purchased a special phased array, or series of microphones, to measure acoustics in this test. The phased array displays sound as color and requires expert application and data processing to get meaningful results.

Tony Opalski of GE installs hardware that will support detailed blade and flow field measurement systems during the test. Image Credit: NASA The project has been intensive -- the experiments in the tunnel have been running in two shifts, meaning testing is going on daily from 9 a.m. to 11 p.m. A crew of about 30 NASA employees has been working with about five GE employees onsite.

Tony Opalski of GE installs hardware that will support detailed blade and flow field measurement systems during the test. Image Credit: NASA The project has been intensive -- the experiments in the tunnel have been running in two shifts, meaning testing is going on daily from 9 a.m. to 11 p.m. A crew of about 30 NASA employees has been working with about five GE employees onsite. "We have had very few issues with the hardware or the data systems. Since we've been up and running, things have gone smoothly with the test," Van Zante says."It's been both fun and challenging, and very dynamic."

Early results are promising, and there is a possibility of testing second generation blade designs with GE after company researchers have analyzed their data. Airplane manufacturers also have expressed interest in using the Glenn wind tunnel and counter rotating rig to test the blade technology with an influence model, which explores changes to the noise and fuel burn reduction when the open rotor is installed on the fuselage of an aircraft.

Both the current tests and the 1980s experiments have measured primarily takeoff and landing noise with minimal cruise noise data. Additional testing planned in the 8' x 6' Supersonic Wind Tunnel at Glenn, where conditions can simulate cruising velocity, will provide data on the high-speed performance of open rotors operating at cruise speeds.

Whatever exciting next steps the inquiry into open rotor calls for, Glenn will be ready with its unique blend of experienced personnel and specialized equipment.

"This drive rig is a unique contribution by NASA Glenn," Brian Fite says. "It's the only drive rig in the country that can do this testing."

NASA's Glenn Research Center

Kaynaklar

Yorumlar

Yorum Gönder